All production facilities available at RBR come under the strict supervision of the Quality Assurance Department. An elaborate system to control and monitor all orders is done through an ERP System, which tracks the status of each order in production.

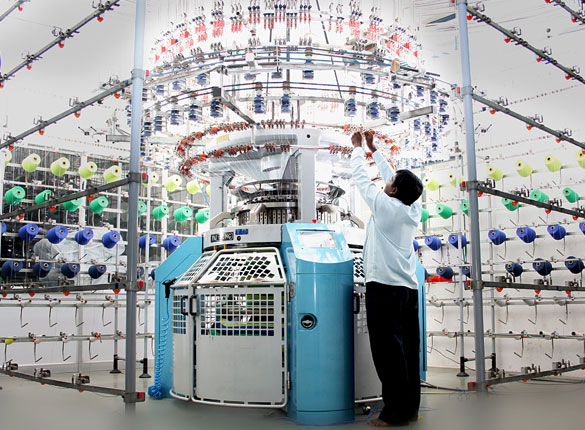

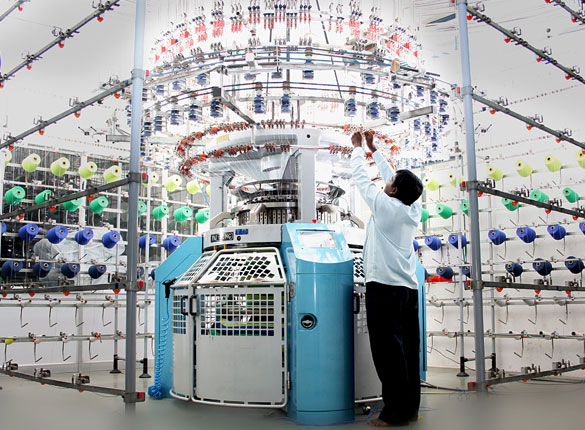

KNITTING

The Very latest 16,20,24 & 28 Gauge Circular Knitting machine are engaged in the production floor like “ Mayer & Cie” from Germany, Italian “ Orizio Paulo” A variety of knitted fabrics are produced starting from the basic jersey, Interlock, Pique, Rib, Auto striper With 70 Color + Lycra, Jacquard + Wrapper with 72 color + Lycra. Collar: - 16 & 114 – Plain + Platted jacquard.

FABRIC DYEING

“Dilmenler” Modern HTHP Soft Flow Dying Machines with superior Control parameters latest SETEX 838 PLC Controller

YARN DYEING

“Dilmenler” yarn dyeing machines are used for an uniform, best and reproducible shades. This is supported further by Mesdan-Italy wet splicing for a smooth knotless knitted stripes and check.

COLOUR LAB

Fully automated Lab dispenser / Colour matching SPECTRO-SF 600 and I.R Lab dyeing machines helps 100% accuracy.

COMPACTING

The washed and laundered cloth is sent through the latest “Tube-tex” USA compacting machine to control shrinkage. All processed fabric is pre-shrunk, so that the garments always retain shaped.

FABRIC MERCERIZING

The RBR fabrics undergo value addition by its additional special Mercerizing process. The mercerizing is done by the only world’s best “Dornier” Germany Mercerizing machine. The specialty with our latest machine is also due to its circular expandable four tower washing facility which is also fully automated, yielding high luster, and intense color depth leaving a very good hand feel.

PPRODUCTION

The Production line for finishing has high-tech 1280 machines like PEGASYS, JUKI, SIRUBA and BROTHER. The well trained and skilled workforce engaged in 32 Lines around 32,000 pcs per day. And finishing all garments is steam- ironed and machine pressed meticulously. All the garments are hand packed with care and stored for subsequent transportation to various destinations.

EMBROIDERY

This department has the world’s best Japanese “Barudan” automatic high-speed embroidery Machines, they are capable of rendering multi colors of embroidery and appliqué, an art which enhance the value of the garments. Capacity 1.5 Billion Stitches per day.

WASHING

All Types of Garment washes like Stone wash, Enzyme Wash, Acid Wash and many more.